RESOURCES

FLAT ROOF TALK: MYTH VS FACT

❌ Myth: Flat roofs always leak.

✅ Fact: A properly installed and maintained flat roof with a tapered insulation system is just as watertight as any other roofing system. Modern materials like TPO, PVC, EPDM, and modified bitumen provide excellent water resistance when installed by professionals. Regular maintenance keeps your roof leak-free!

🔍 Tip: Schedule routine inspections to catch minor issues before they become major leaks.

❌ Myth: Flat roofs don’t last long.

✅ Fact: With proper installation and maintenance, flat roofs can last 20+ years! Materials like EPDM, PVC, and reflective coatings can extend the life of your roof even further.

📅 Tip: A proactive maintenance plan can help you maximize your roof’s lifespan and avoid unexpected costs.

❌ Myth: Flat roofs can’t handle heavy rain or snow.

✅ Fact: Flat roofs are designed with proper drainage and structural support to withstand heavy loads. Routine maintenance ensures drains stay clear, preventing ponding water and excess buildup.

💡 Tip: After a major storm, check drains and gutters to keep water flowing off your roof.

❌ Myth: Flat roofs have no insulation and make buildings inefficient.

✅ Fact: Today’s flat roofing systems include high-performance insulation that meets or exceeds energy codes, helping reduce heating and cooling costs. White reflective membranes can also lower cooling expenses.

🔎 Tip: Consider an energy-efficient roofing system to improve comfort and save on utilities.

❌ Myth: Flat roofs require constant repairs.

✅ Fact: Routine maintenance keeps flat roofs in top shape with minimal effort. Modern materials are highly durable, and preventative maintenance helps avoid costly repairs.

🔧 Tip: Spring and Fall routine maintenance help catch small issues before they turn into major problems.

❌ Myth: Flat roofs are completely flat.

✅ Fact: Most “flat” roofs are actually low-slope roofs, built with just enough pitch to allow water to drain efficiently. That slight slope is crucial for preventing ponding waterand extending the roof’s lifespan.

📏 Tip: A well-designed low-slope roof directs water to drains, scuppers, or gutters—keeping your building dry and protected.

ROOF SYSTEM RUNDOWN

Not all roofs are created equal! Whether you’re managing a commercial property, an industrial facility, or a medical center, choosing the right roofing system is key to performance and longevity. Let’s break down the most common low slope roof types – pros, cons, and best applications.

TPO Roofing: A Smart Choice for Energy Savings!

TPO (Thermoplastic Polyolefin) is a lightweight, highly reflective roofing system designed to keep buildings cooler and reduce energy costs.

✅ Heat-welded seams for strong waterproofing

✅ UV-resistant & energy-efficient

✅ Great for commercial & industrial buildings

✅ Color options for aesthetics in high visibility areas (like a hotel roof top patio)

⚠️ Needs skilled installation for long-term durability

PVC Roofing: Built Tough for Tough Environments!

PVC (Polyvinyl Chloride) is a strong, flexible, and highly durable single-ply membrane, perfect for buildings exposed to grease, chemicals, and harsh weather.

✅ Excellent chemical resistance (great for restaurants & factories!)

✅ Heat-welded seams for superior waterproofing

✅ Long-lasting and flexible

⚠️ Higher cost than TPO, but worth the investment for the right setting

EPDM Roofing: The 25+ Year Powerhouse!

EPDM (Ethylene Propylene Diene Monomer) is a rubber roofing system known for its long lifespan and weather resistance.

✅ Withstands extreme temperatures & UV exposure

✅ One of the most cost-effective, long-term solutions

✅ Can be installed in different ways—ballasted, adhered, or mechanically fastened

⚠️ Standard black EPDM absorbs heat

Built-Up Roofing: Reliable in the Past—But What About Today?

BUR (Built-Up Roofing) was a go-to system for decades, known for its heavy-duty layers of asphalt and gravel. But like rotary phones and floppy disks, even the most trusted systems eventually get outpaced.

⚠️ Common issues with aging BUR roofs:

🔹 Cracking from temperature swings

🔹 Heavy weight that stresses structural supports

🔹 Labor-intensive and messy repairs

Modern systems like TPO, PVC, and EPDM offer:

✅ Greater energy efficiency

✅ Lower maintenance demands

✅ Lighter weight and faster installation

Modified Bitumen: Once Popular. Still Common. But Is It the Best Option Today?

Modified Bitumen became popular as a step up from traditional BUR systems—offering more flexibility and easier installation. But while it still shows up on commercial buildings, today’s roofing technology has come a long way.

⚠️ Challenges with Modified Bitumen:

🔹 Seams can degrade over time

🔹 Limited energy efficiency unless coated

🔹 Requires specific installation methods to avoid failure

Looking at a re-roof or capital improvement plan? Modern membranes like TPO and PVC often outperform Modified Bitumen in:

✅ Reflectivity and energy savings

✅ Seam strength and leak prevention

✅ Installation versatility

Which Roofing System is Best for Your Property?

Now that we’ve covered the most common options, here’s a quick guide to help you decide:

🔹 TPO – Energy-efficient & cost-effective

🔹 PVC – Great for chemical resistance & durability

🔹 EPDM – Long lifespan & weather-resistant

🔹 BUR – Heavy weight & labor intensive

🔹 Modified Bitumen – Limited energy efficiency & degrading

Still unsure? We’re happy to help! Contact us for expert advice.

WEATHER TIPS

Heavy Rain & Ponding Water

After heavy rain, check for standing water on your flat roof. Ponding water can lead to leaks, membrane damage, and structural issues if left unchecked. Preventative maintenance helps prevent costly repairs!

Wind Damage Isn’t Always Obvious

High winds can do more than just rattle the windows. They can lift metal flashing, loosen seams, and toss debris onto your roof – all of which can lead to hidden damage and drainage issues. Even small pieces of debris can puncture membranes or clog rooftop drains.

After any strong wind event, hire a professional to inspect your roof to look for signs of trouble.

Hail Impact & Hidden Damage

Hail damage isn’t always obvious! Look for dents, cracks, or punctures in the membrane or metal and inspect rooftop equipment for impact marks. Catching small damage early prevents bigger issues later.

Snow Load & Structural Stress

Heavy snow adds significant weight to your roof, potentially causing structural stress. Monitor accumulation and call a professional for safe snow removal.

Ice Dams & Drainage Issues

Ice dams form when heat escapes, melting snow that refreezes at the roof edges. This can block drainage, causing water to back up under the membrane. Proper insulation and routine maintenance help prevent costly leaks. Seeing icicles or ice buildup on your roof? It might be a sign of an issue! Call us for removal or an inspection.

Freeze-Thaw Cycles & Roof Cracks

Repeated freezing and thawing can cause roofing materials to expand and contract, leading to stress and deterioration. Spring and Fall maintenance can help catch small issues before they become big problems!

Rainy Days Can Bring Roof Surprises

Heavy rain can reveal weaknesses in your roof—like open seams, failed flashing, or poor drainage. If water enters your building or stains appear on ceilings, the leak may have started days (or even weeks) ago.

Flat Roofs & Poor Drainage Don't Mix

Flat roofs rely on clean drains and proper slope to move water off the surface. When drains are clogged with debris, even light rain can lead to ponding, which speeds up membrane deterioration and invites leaks.

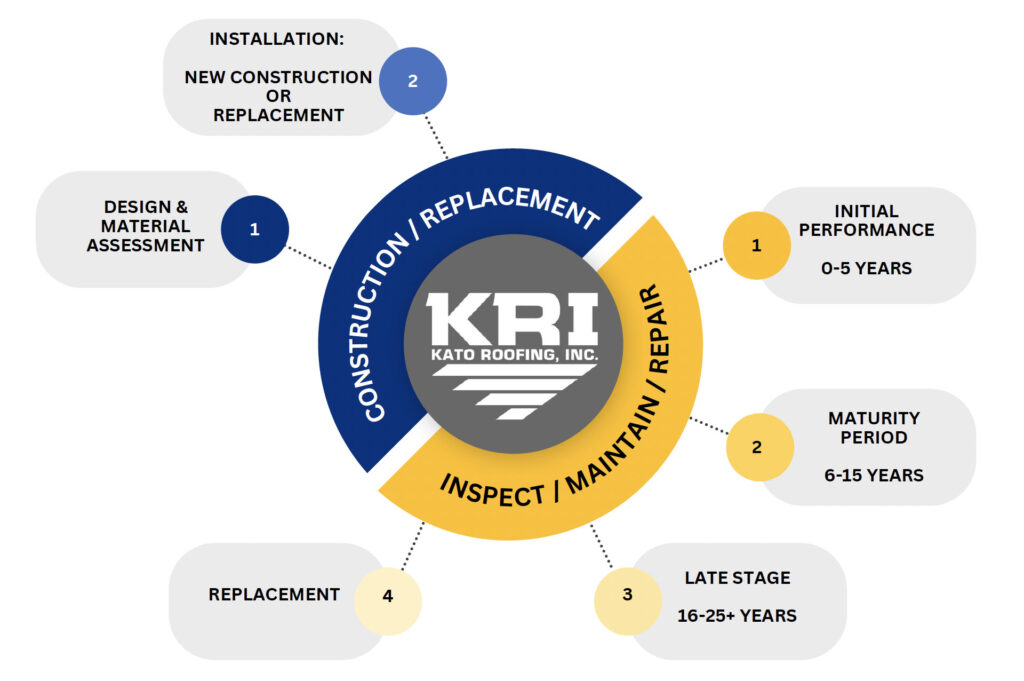

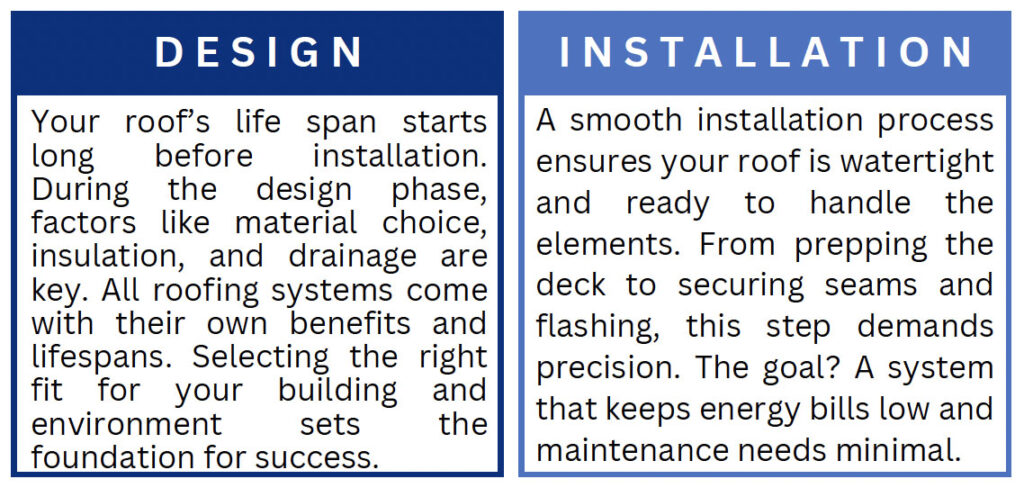

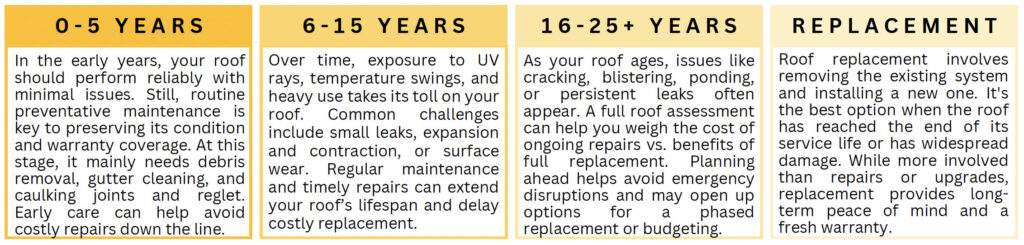

LIFE CYCLE ROOF MANAGEMENT

The life cycle of a commercial flat roof refers to the various phases it undergoes from installation to replacement. Each stage involves specific maintenance and considerations to maximize the roof’s performance and longevity. No matter the stage of your roof in its life cycle, WE’VE GOT YOU COVERED!

ROOF SYSTEMS

The roofing industry constantly strives to create new and better design concepts. Kato Roofing partners with the industry’s leading manufacturers and associations to ensure we comply with industry standards and best practices on every installation. When we start a job, we don’t stop until the project is complete. That means we complete every detail, right down to the gutters, soffit, and fascia.

RUBBER (EPDM)

Worldwide, EPDM is the most popular type of roofing for both new and reroof low-slope applications. It is durable, extremely versatile, and easy for roofing professionals to install, maintain and repair.

EPDM roofing systems are based on a high-performance synthetic rubber compound, available in black or white. Advantages include high strength, low weight, and outstanding thermal expansion and contraction characteristics.

EPDM membranes have a 30-year record of proven weatherability in all types of climates. They are waterproof, highly resistant to ultraviolet deterioration, and well suited to applications ranging from office buildings, to warehouses, to hospitals, and schools.

BUILT-UP (BUR)

BUR is a durable roofing system ideally suited to low-slope or flat roofs structures and is constructed of multiple layers of asphalt and fiberglass “felts”.

The redundancy of a multi-layered system provides greater puncture resistance and protection against leaks. Asphalt works well as both an adhesive to bond the felts together and as a water resistant material to prevent moisture penetration.

KRI uses manufacturer designed base, ply, and cap sheets, along with the proper installation tools, to provide the highest quality asphalt-based roofs.

THERMOPLASTIC POLY OLEFIN (TPO)

Thermoplastic single-ply roofing membranes are among the fastest growing commercial roofing products and have gained broad industry acceptance for their many performance and installation advantages.

At a time of increasing demand for more energy efficient roofing systems, TPO single-ply membranes offer high reflective qualities to reduce cooling costs and the urban heat effect. TPO has exceptional resistance to ultraviolet, ozone, and chemical exposure.

TPO is a great reroofing option and is most commonly used for flat roofing structures.

POLY VINYL CHLORIDE (PVC)

PVC is a rigid thermoplastic that relies on plasticizers for flexibility and additives for UV protection. As a thermoplastic, it can be heat welded at seams to produce a continuous roofing surface.

KRI only uses PVC sheet manufacturers using high quality plasticizers with an established record of superior performance. The material is frequently specified for restaurants due to its grease resistant qualities.

MODIFIED BITUMEN

Modified Bitumen is a membrane consisting of asphalt with added plasticizers for flexibility, and a reinforcing scrim for strength.

It is well-suited for use in flashings or when installed as a cap sheet for a built-up roof system. Modified Bitumen is also an excellent candidate for high-traffic roof areas and features a granular surface available in multiple colors.

COATINGS

The roofing industry utilizes a number of elastomeric coatings, ranging from acrylic to urethane. Coatings can be quickly applied to asphalt, EPDM, PVC, or other membranes to extend the useful life of the roof by 10 years or more.

Coatings can provide additional waterproofing for metal surfaces, or increase the reflectivity of a membrane to help reduce cooling costs.

Today’s coating systems offer substantial savings to contractors and building owners by using technology to maximize roof performance and lower labor expenses.

TAPERED INSULATION SYSTEMS

Kato Roofing, in conjunction with our suppliers and manufacturers, has the ability to design a tapered insulation system made specifically for your building. We will take into consideration the type of drainage, where you would like the water to end up, and slope of the roof. A good roof will drain properly within a reasonable amount of time, reducing the chance of water infiltration into the building.

STANDING SEAM ROOFING SYSTEMS

The roofing industry utilizes a number of elastomeric coatings, ranging from acrylic to urethane. Coatings can be quickly applied to asphalt, EPDM, PVC, or other membranes to extend the useful life of the roof by 10 years or more.

Coatings can provide additional waterproofing for metal surfaces, or increase the reflectivity of a membrane to help reduce cooling costs.

Today’s coating systems offer substantial savings to contractors and building owners by using technology to maximize roof performance and lower labor expenses.